[adrotate group="2"]

Is Apple’s Manufacturing Dream Turning Into a Nightmare?

Buckle Up, America! The iPhone’s Big Move Faces Insurmountable Challenges!

Just when you thought it was possible to revolutionize U.S. manufacturing, reality slams its door shut! Moving Apple’s production to the Land of the Free? That’s going to take years—if not decades! We’re talking a monumental effort to juggle investments in automation, tools, and training while trying to convince foreign manufacturers to pack up and move to the U.S.

Chinese Manufacturers Hold All the Cards!

Wait! If you’re a Chinese supplier with your hands on components used in popular brands like Huawei and Xiaomi, guess what? You’ve got the leverage, my friends! Why would you even think about splitting up factories when the scales of efficiency in China are so tantalizing? That means less incentive to change for Apple, and we all know how that ends!

Policy Whiplash: The Business Killer!

But hold on! The chaos doesn’t stop there. With the U.S. government flipping the script every four years, how can any business plan for the future? It’s a recipe for instability and uncertainty. Investments demand a long-term horizon—something the current American landscape doesn’t seem to provide!

The Tough Love of Labor Costs!

Let’s dive deeper! Mark Randall, a pivotal player at Motorola back in the Google days, knows one thing for sure: turning raw materials into shiny gadgets isn’t just a breeze in the U.S. Labor costs here are astronomical compared to other parts of the globe. Plus, there’s a dire shortage of mechanical tooling engineers. To pull off a massive shift, we’d need tens of thousands—and fast!

Tariffs Wreaking Havoc!

Tariffs? Oh, baby, they create a costly nightmare for planning any new plants! No wonder companies are hesitant to make hasty moves in this rollercoaster economy. It’s all about being super strategic and knowing your path in this chaotic landscape!

Made in America? Not So Fast!

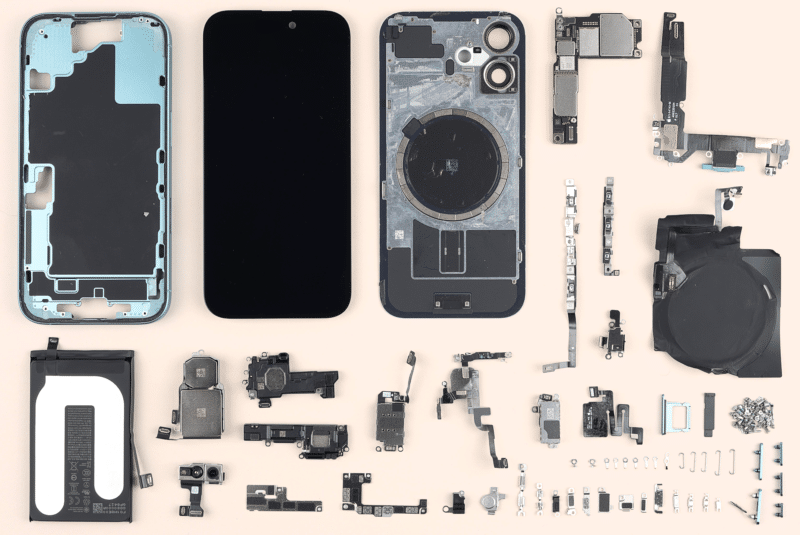

Take a closer look at those latest iPhone models—it’s a tangled web of complexity! Sure, the cover glass is made by Apple’s trusted partner Corning in Kentucky, but hold your horses! The OLED displays essential for that battery magic are mostly Samsung-made in South Korea.

And let’s not forget, the heart of the iPhone? It gets assembled in China before its grand debut at the Foxconn plant. Can you say difficult?

Aluminum Dreams Turn to Dust!

Now, about that sleek metallic frame—it symbolizes just how tough yanking China from Apple’s supply chain will be. Each casing is meticulously carved from a block of aluminum using high-precision CNC machines. But wait! There’s an army of these machines in China, and replicating that elsewhere? Next to impossible!

Even Screws Are a Headache!

Don’t underestimate even the tiniest iPhone screws! Made from various materials and equipped with multiple head types—this isn’t child’s play! Apple’s unique design rejects glue and insists on a labor-intensive screwing process. Guess what? It’s cheaper for Foxconn to stick with humans than invest in robotic solutions.

The blatant truth? Apple’s dream of U.S. production is teetering on the edge of an industrial cliff! Will they conquer these hurdles, or are we witnessing the fall of a giant? Only time will tell, but the stakes couldn’t be higher!

photo credit: ig.ft.com

[adrotate group="2"]